Model #

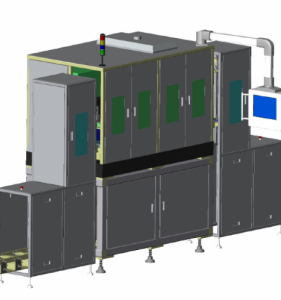

NSI-UC2-3228 Gen III

General Info

Our Hybrid UV and CO2 laser system is a versatile laser processing solution ideal for recipe development and experimenting with new materials. This system is suitable for R&D and complex applications that require higher precision and more controlled laser processing capabilities. Our laser micromachining capabilities include via drilling, cutting, routing and skiving.

The combined UV and CO2 laser system are perfect for PCB (printed circuit board) processing. The UV laser is ideally suited for fast and efficient drilling of copper layers whereas the CO2 laser is better suited for the acrylic layer of the PCB. Combined, the UV/CO2 provides a single step setup for drilling through multilayer PCBs.

NSI has perfected its hybrid system (laser drilling of both copper layer and dielectric composite materials) with an emphasis for user-friendliness.

Key Features

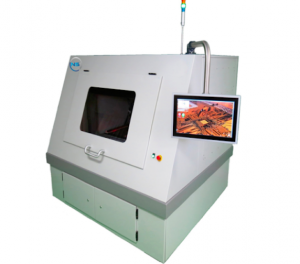

Laser: 15w-20w UV and 3kw high peak power CO2

Max Panel Size: 32″ x28″

CCD camera vision