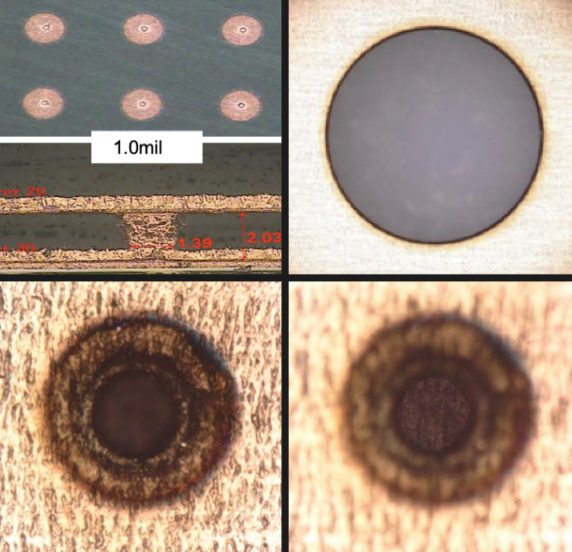

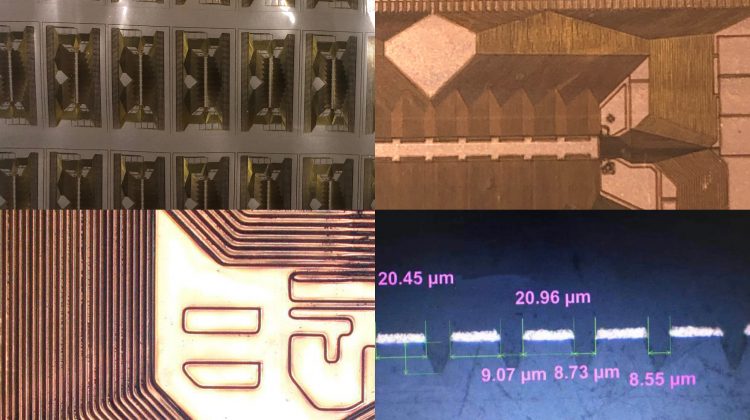

The advantages of the combined UV and CO2 laser system are directly related to PCB (printed circuit board) processing. The UV laser is ideally suited for fast and efficient drilling of copper layers whereas the CO2 laser is uniquely suited for the acrylic layer of the PCB. In combination, the UV/CO2 provides a one-time setup for drilling through multilayer PCBs.

The advantages of the combined UV and CO2 laser system are directly related to PCB (printed circuit board) processing. The UV laser is ideally suited for fast and efficient drilling of copper layers whereas the CO2 laser is uniquely suited for the acrylic layer of the PCB. In combination, the UV/CO2 provides a one-time setup for drilling through multilayer PCBs.

Capabilities:

- Drilling holes with diameters ranging from 1 – 20 mils (25μm – 500μm). Formation of blind-via and step via holes.

- Skiving of fiducial marks for drill file registration.

- Routing of different substrate PCB materials.

Hybrid UV and CO2 laser system (laser drilling of both copper layer and dielectric composite materials).

Model: NSI-UC2-3228

- Laser: 15w-20w UV and 3kw high peak power CO2

- Max Panel Size: 32″ x28″

- Panel compensation (offset, rotation and scaling X/Y versus alignment marks)

- CCD camera vision

Hybrid UV/CO2 laser drilling system