Laser Micro-machining Equipment Design and Manufacturing

International Support

Available through both online and in person, our tech support is not limited by distance

Precise Micromachining

Laser drilling, routing, cutting, depanelling, scribing, skiving etc. all up to 15 microns of precision with our custom routing software

Automation Integration

Utilize automation to help improve your laser system’s efficiency and speed

Our machines

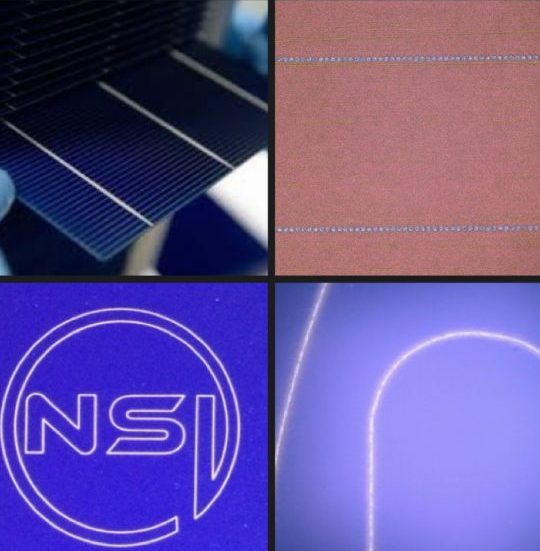

The NSI UV FLEX Dual Beam System is an advanced laser processing solution with high precision and volume FPC, LCP, COF production. Possessing high efficiency and optimal routing functions, this system is designed for fine feature laser routing. It comes with NSIconverter™️ software which converts drilling patterns to isolation routes. Additional micro-machining capabilities include cutting, depanelling, microvia drilling, scribing and skiving.

The NSI UV-FLEX-500 series is an affordable laser processing solution best for mass production. The system is suitable for high throughput and high yield applications that require multiple laser processes include via drilling, cutting, depanelling, routing, and skiving.

The NSI-GWS-170S laser system is designed for PERC cell back scribing process and other micromachining processes such as drilling, skiving, and scribing. It can be used as a standalone system or be integrated into an inline mass production line.

Our services

application lab

Equipped with multiple laser systems, our application lab can perform sample tests for different processes in the aerospace, medical, military, solar, and electronics industries. We also provide advanced metrology, including equipment such as 3D profilers and optical microscopes. We also offer a more in depth analyses through cross-sections and SEM analysis at material characterization facilities in Silicon Valley.

job shop

Test out your prototypes and concepts at NSI’s job shop. Our team has years of experience in laser processing in ablation, cutting, and drilling. With our production ready tools, we validate manufacturability and conduct initial production runs to demonstrate the potential of your process for volume production.

calibration & maintenance

Online and/or on-site, our technical team provides worldwide engineering services and system support such as full calibration and maintenance services.

Main Applications

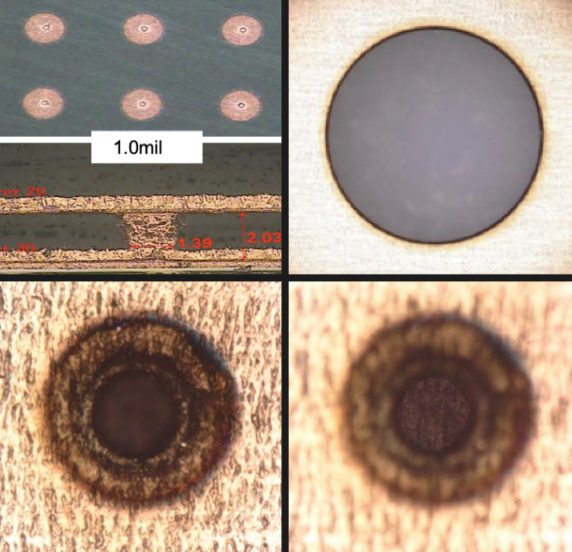

via drilling

NSI LASER is continually developing and adding new hole drilling processes and capabilities. Typically we can drill material that range in thickness from very thin films to several mm’s on a high speed setup that can drill thousands holes quickly and repeatably. Depending on the material and specifications, we will choose the optimized tool to drill the holes.

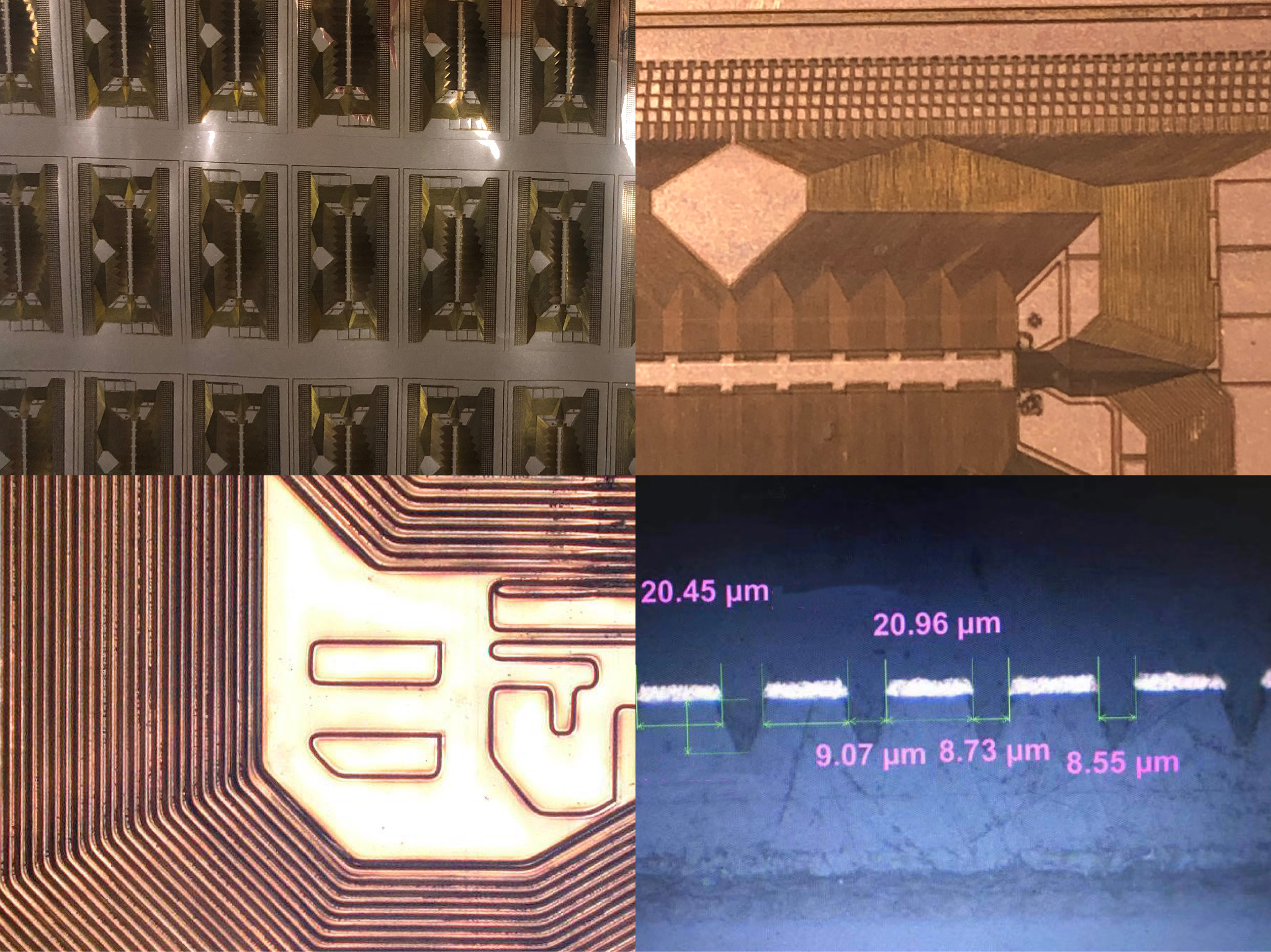

isolation routing

With NSIconverterTM, we can convert Gerber files into isolation routing files. By optimizing the routing path to become compatible with the laser route, we can achieve higher accuracy and quality. Our machine can process fine line/space as small as 15 micron.

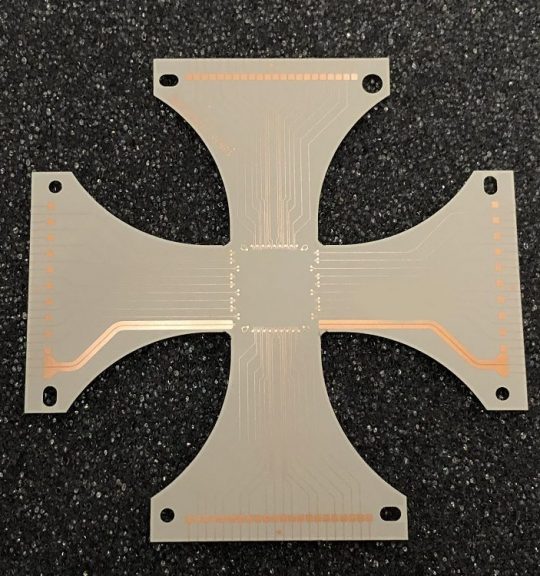

cut and depaneling

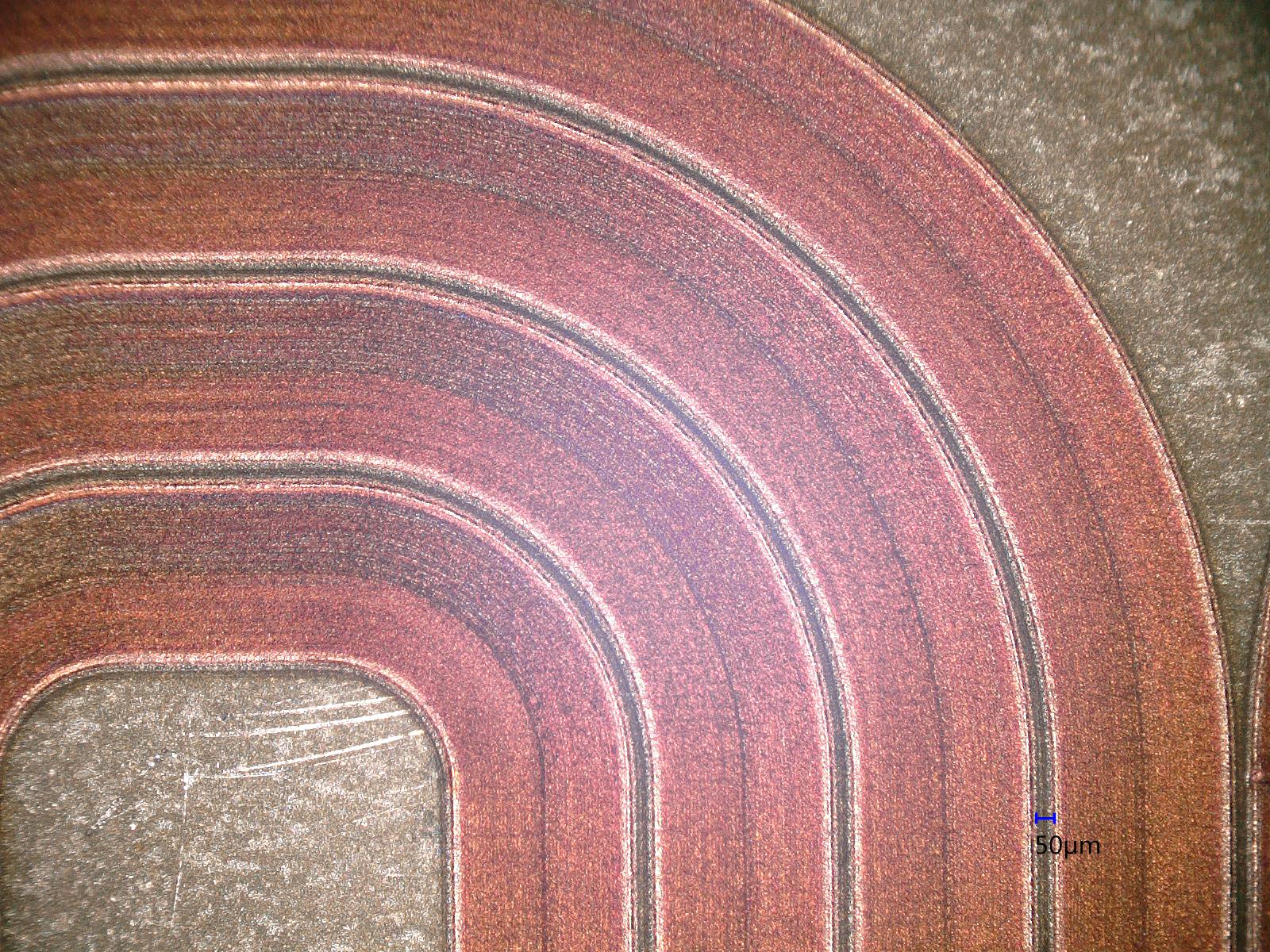

hatching & skiving

Our machines can remove material to reveal fiducial marks through both hatching and skiving. Our hatch function can process complex patterns to create prototype PCB and allow you to control the overlap to help develop finer recipes.

scribing

Our machines also have scribing functionality that enables you to mark or label your materials.

Interested?

and find out if we’re the right choice for you